Developers

Engineered to Deliver.

Your Specialists in Cold Formed Steel.

Offering end-to-end full service with multiple framing options, efficiency, ROI, compliance & reliance.

From concept to construction without disruption.

Our engineering. Your development. One seamless build experience.

Whether you’re delivering residential communities, commercial buildings, modular estates, tiny home villages, or large-scale mixed-use developments, our role is simple:

Customize, reduce waste, create ROI on small, medium or larger scale and take the headache out of engineering and permits.

Replace lumber for panalized cold-formed steel framing making your project more streamlined.

Past Projects

Apartment Project

Holiday Inn - Arizona

Holiday Inn - Texas

Strip Mall

New Orleans

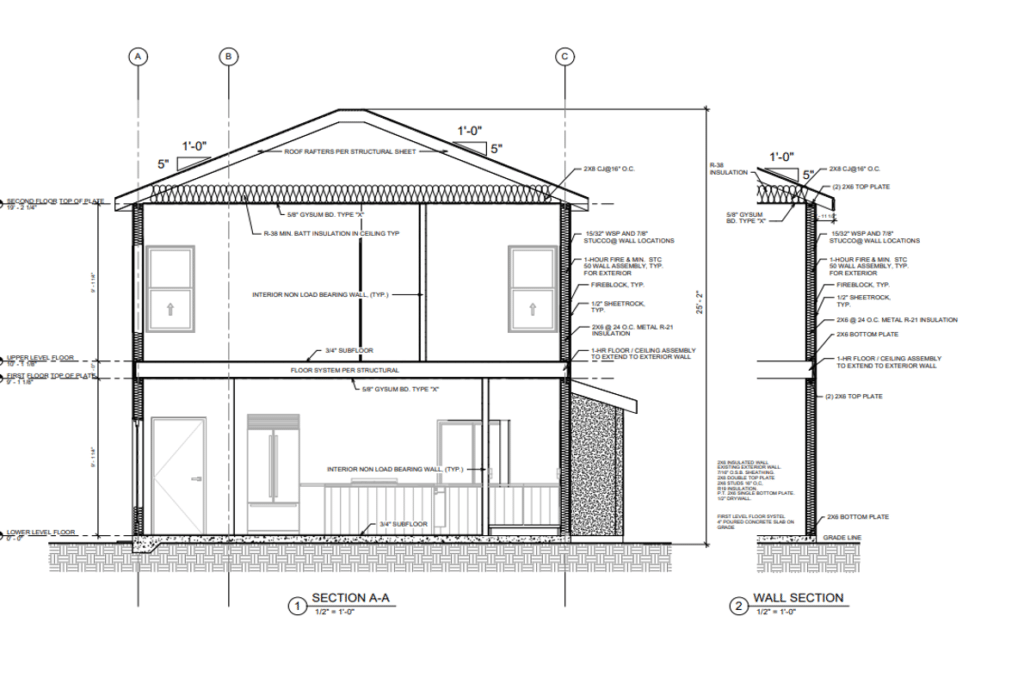

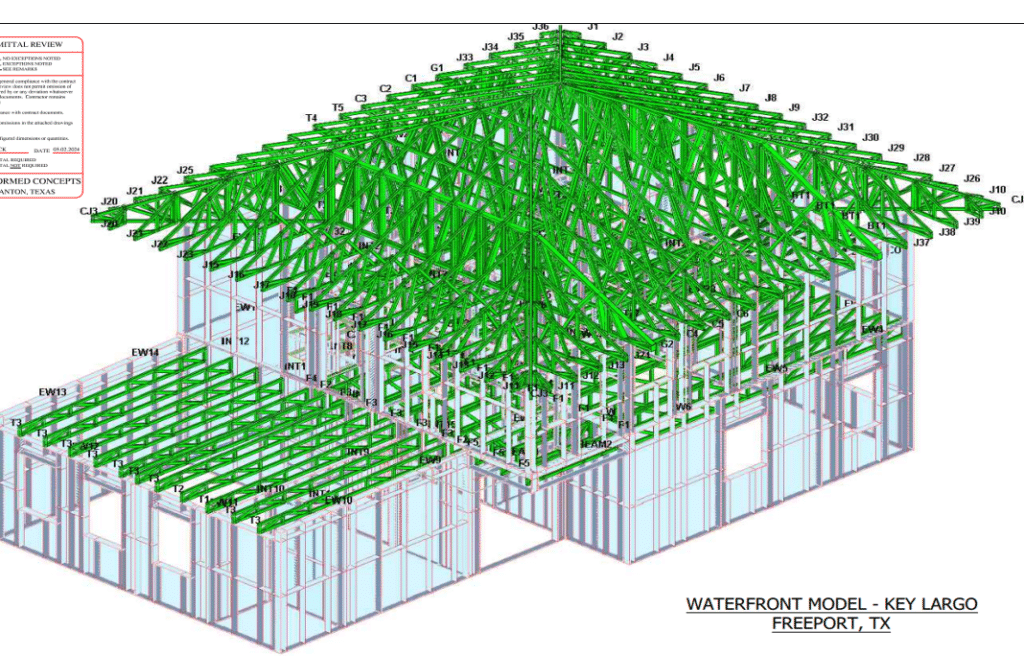

Key Largo

Key Factors Driving ROI with Us

We manage engineering, permits, manufacturing, delivery, and installation

End-to-End Delivery

Concept > Engineering > Permit Packages > Manufacturing > Construction

Three Framing Options

CFS - Hybrid Weather Kits - Modular

Environment-Ready Engineering

Hurricane - Seismic - Tornado - Snow Load

Framing Engineering & Manufacturing.

Step-By-Step Developer Process

Step 1 - Submit Architectural Plans (CAD/DWG Required)

Developers provide architectural drawings in CAD/DWG format so engineering can begin.

This ensures accurate structural design and manufacturing coordination.

Step 2 - Engineering Begins (4–6 Weeks)

Our engineering team works directly with your architect to:

- Analyse footprints, load paths, spans

- Determine CFS gauges (16–20 gauge)

- Confirm stud sizes (5.5″, 6″, 3.5″, 3 5/8″)

- Identify any red-iron requirements based on levels, span lengths, and structural demands

Engineering produces a complete, build-ready framing system.

The Permit Submittal Package includes essential components such as:

- MEP plans (mechanical, electrical, and plumbing) Plans

- Comprehensive architectural plans

Site plans - Title 24 compliance (if necessary)

- Energy requirement sets (if needed)

- Structural engineering calculations specifically tailored for the steel stud framing system or other building systems.

- Foundation blueprint plans designed by an engineer for your structure or home.

Step 3 - Foundation & Connection Design

We review or design the foundation to match the structure:

- Slab, stem wall, pier, or custom foundations

- Anchor placement and connection details

- Fastener schedule and load transfer points

This ensures the frame integrates seamlessly with your foundation contractor.

Step 4 - System Creation & MEP Integration

Once engineering is approved, we create the full CFS building system.

During this stage we:

- Pre-punch stud holes for electrical and plumbing

- Add straps or extra studs for TVs, cabinets, or A/C units

- Provide C-channel patterns that allow easy 2×4 or 2×6 wood blocking on site

This step produces your final, construction-ready framing package.

Step 5 - Fabrication at Closest Facility (4–6 Weeks)

Fabrication starts immediately after engineering sign-off.

We manufacture panels at the closest facility to your project for fast delivery.

This stage includes:

- Precision cutting, forming, and labelling

- Packaging panels in erection order

Shipping coordination so panels arrive when your foundation is ready

Step 6 - Delivery to Site

The frame arrives on site either:

- Just in time for slab completion, or

- Earlier, based on your schedule

Panels are clearly labelled and sequenced for rapid installation.

Step 7 - On-Site Installation Support (Up to 5 Days)

Our team provides on-site assistance to help your crew erect the structure.

Support includes:

- System walkthrough

- Panel sequencing

- Troubleshooting

- Best-practice guidance for teams new to CFS

The building system is designed so semi-skilled or unskilled crews can erect it confidently.

Your next project starts today

Our mission is straightforward yet impactful

“To offer convenient and cost-effective project experiences for our clients.”

We specialize in customizable building models designed to withstand a variety of environmental challenges, including seismic activity, hurricanes, tornadoes, and heavy snow loads. Our steel-based kits provide resilience against extreme weather conditions, safeguarding our clients’ investments. We are committed to understanding our clients’ needs and providing the best building solutions for their projects.