The Hybrid Approach

Options for Connecting Wood Trusses to CFS Walls

In hybrid construction, connecting wood trusses to Cold-Formed Steel (CFS) walls requires specific methods to ensure structural integrity, efficient installation, and alignment with design requirements. Below are the two primary connection methods, considerations for hybrid systems, steps for transitioning to a hybrid approach, and benefits of hybrid construction. Additionally, recommendations for attaching sheathing to CFS walls using specialized tools have been updated.

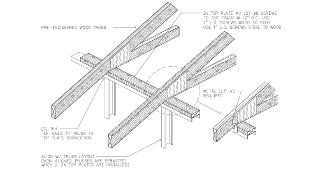

Option 1: Using a Wood Top Plate on the CFS Wall

Overview

A wood top plate is installed on top of the CFS wall, acting as a base for attaching wood trusses.

Connection Details

Securing the Wood Top Plate to the CFS Wall:

- Use self-drilling screws (e.g. #10 or #12 screws) to fasten the wood top plate to the steel studs.

- Screw spacing is typically 6” to 12” on-center, depending on the load requirements.

Securing the Trusses to the Wood Top Plate:

Use standard wood fasteners, such as nails or truss anchors (e.g., Simpson Strong-Tie H2.5A), to attach the trusses to the top plate.

Benefits

- Simplifies construction by maintaining traditional wood-to-wood connections.

- Provides flexibility in truss alignment and easier handling during installation.

Stud and Truss Spacing

The CFS stud spacing must match the truss layout:

- For trusses at 24” on-center, use 24” on-center spacing for CFS studs with 18-gauge material.

- For trusses at 16” on-center, use 16” on-center spacing for the CFS studs.

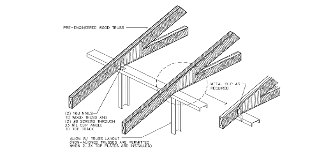

Option 2: Direct Attachment of Wood Trusses to CFS Wall

Overview

The wood trusses are directly attached to the CFS studs using metal brackets or specialty connectors.

Connection Details

Securing Brackets to CFS Studs:

- Use self-drilling Tek screws (e.g. #10 or #12 screws) to fasten metal brackets or connectors to the steel studs.

- Screw spacing is critical for structural integrity and follows engineering specifications.

- Securing Trusses to Brackets:

- Use wood screws or nails recommended by the bracket manufacturer to attach the trusses to the metal connectors.

Benefits

- Provides a direct load path from trusses to the CFS wall, increasing strength and stability.

- Eliminates the need for a wood top plate, reducing material usage.

Stud and Truss Spacing

The CFS stud spacing must align with the truss layout:

- For trusses at 24” on-center, use 24” on-center spacing for CFS studs with 18-gauge material.

- For trusses at 16” on-center, use 16” on-center spacing for the CFS studs.

Attaching Sheathing to CFS Walls

Tool Recommendation

Use an Aerosmith ST4200 Versa Pin Gun for attaching sheathing to CFS walls. This tool is optimized for speed and precision when fastening sheathing materials such as OSB, plywood, and cement board.

Fastener Recommendations

Use VersaPin 2385AG pins, specifically designed for attaching sheathing to CFS.

The Aerosmith Fasteners (2385AG, 2359NG and 5454 HPG for subfloors ¾ to 1 ¼ “) are pneumatically driven fasteners used to attach floor and roof sheathing to cold-formed steel framing (CFS) members. The fasteners may be used to attach wood sheathing to CFS in structures regulated by the IRC, provided an engineered design is submitted in accordance with Section R301.1.3 of the IRC.

Recommended PSI Settings

- For 18-gauge CFS, set the air pressure to 105 PSI.

- For 16-gauge CFS, set the air pressure to 110 PSI.

Benefits of the Aerosmith System

- Faster Installation: Eliminates pre-drilling or manual screw fastening, speeding up construction.

- Consistent Fastening: Ensures uniform attachment of sheathing to CFS walls, enhancing structural integrity.

- Ease of Use: Ergonomic design reduces worker fatigue and increases productivity.

- Cost-Effective: Saves on labor costs by significantly reducing installation time.

- Versatility: Compatible with a wide range of sheathing materials.

Transitioning to a Hybrid Approach

What Is It Called?

- This process is known as a Material Change Request or Material Substitution when transitioning from traditional wood framing to a hybrid system using CFS.

Steps to Transition

- Review Existing Drawings:

- If you already have wood-framed drawings, consult with a structural engineer to adapt them for a hybrid system.

- Engineering Update

- The structural engineer will update the plans to reflect the new CFS components while retaining wood trusses or other elements.

- Permit Revision

- Submit the updated plans to the local building department as a permit revision or amendment.

- Alignment with Codes

- Ensure all updates meet local building codes for hybrid construction, including wind, seismic, and fire safety requirements.

Hybrid Connection Benefits

- Cost Efficiency

- Pre-fabricated CFS components and tools like the Aerosmith ST4200 reduce labor hours and material waste.

- Faster construction timelines save on general overhead, including insurance, security, and equipment rentals.

- Faster Construction

- Pre-fabricated CFS panels and lightweight wood trusses streamline assembly, reducing build times by up to 70%.

- Durability

- CFS resists pests, fire, and moisture, ensuring long-term structural integrity.

- Design Flexibility

- Adaptable to various layouts and zoning requirements, including seismic and wind-prone areas.

- Improved Energy Efficiency

- CFS walls with advanced insulation options (e.g., spray foam) can reduce heating and cooling costs.

How Hybrid Construction Reduces Costs

- Labor Savings

- Pre-fabricated CFS panels and tools like the Aerosmith ST4200 Versa Pin Gun reduce labor hours and installation time.

- Faster Project Timelines

- Shortened construction periods save on overhead costs such as insurance, security, and equipment rentals.

- Lower Maintenance Costs

- CFS’s resistance to pests, rot, and fire reduces long-term repair and replacement expenses.

- Optimized Material Use

- Steel is used where durability matters, while wood is used for non-load-bearing applications to balan

Conclusion

Both connection methods for hybrid systems—using a wood top plate or direct brackets—offer reliable and efficient solutions for combining wood trusses with CFS walls. Incorporating tools like the Aerosmith ST4200 Versa Pin Gun for attaching sheathing ensures faster construction, reduced costs, and enhanced durability. By transitioning to hybrid construction through material change requests, aligning stud and truss spacing, and utilizing the benefits of both materials, hybrid systems deliver a cost-effective, durable, and efficient solution for modern construction.