Cold-Formed Steel Building Systems

Light & Strong, Straight & True, 100% Termite Proof & Non-combustible.

Built & Engineered for any USA State, especially the harsh weather areas.

Are you facing challenges with your current building projects, such as material inefficiencies, high labor costs, or structural durability issues?

These common problems can delay your project timeline, increase costs, and compromise the integrity of your build. At Well Done 1 Homes, we have the solution to these challenges: Cold-Formed Steel (CFS) building framing solutions.

Building with Confidence Begins with the Right Framework

Superior builds start with superior materials. That’s why our structures are framed with Cold-Formed Steel (CFS). Builders who value precision, strength, and sustainability.

Our Steel: Built to Last.

Our homes are built with Cold-Form Steel (CFS). A high strength, precision engineered material shaped at room temperature rather than heat rolled. This process gives the steel exceptional durability, lightweight performance and is environmentally sustainable.

What is Cold-Formed Steel

Cold formed steel is the advanced material behind our framing. Lightweight yet incredibly strong, it allows for greater design flexibility and long-term performance. Every section is made to exact measurements, ensuring your home’s structure remains straight, true and secure over time.

Eco-Friendly and Sustainable

Cold-formed steel is an environmentally responsible building material, made with minimal waste and often from recycled content. Termite and moisture resistant, it ensures your home’s structure remains strong for decades. More on Benefits.

CFS Stud Framing

CFS stud framing uses cold-form steel to form the walls, floors and roof framework of the home. These steel studs and tracks replace traditional wood framing, offering a more sustainable, fire resistant and low maintenance alternative.

Why It Matters

Choosing CFS framing means choosing strength, safety, and longevity. It’s the modern way to build homes that stay solid, straight, and beautiful for generations to come.

Discover more on building with the right framework and speak with a consultant today.

No Project Too Big or Too Small

How We Work

From concept to full plans, we can work with your designs.

Send Us Your Plans: Whether you have detailed architectural drawings, a simple sketch, or just a concept, we can work with it.

Custom Design: Our expert team will create a customized CFS framing solution that meets your specific requirements.

Build: Benefit from the superior performance and sustainability of CFS steel stud framing.

Already Have Approved Plans and Permits?

We can seamlessly convert your design – wood, block, or any other building system – into a CFS building system. Our engineering and building system division will ensure a fast and effective conversion that meets all your needs.

The Future of Building Belongs Here

On-Site Support and Training

We also offer a qualified consultant to come to your site during construction. They will assist and train your team on our building system at no extra cost, ensuring smooth implementation and the highest quality standards.

Solutions and Added Value

By choosing CFS steel stud framing, you are opting for a building system that addresses common construction challenges such as material inefficiencies, high labor costs, and structural durability issues.

CFS provides:

Efficiency: Reduced waste and faster construction times.

Cost Savings: Lower overall construction costs due to precision engineering and minimal waste.

Longevity: Structures that stand the test of time with superior durability and resistance to environmental factors.

Don’t wait to start building your dream.

Contact us today to learn more about our CFS building system options and discover how we can bring your project to life with the many benefits of CFS steel stud framing.

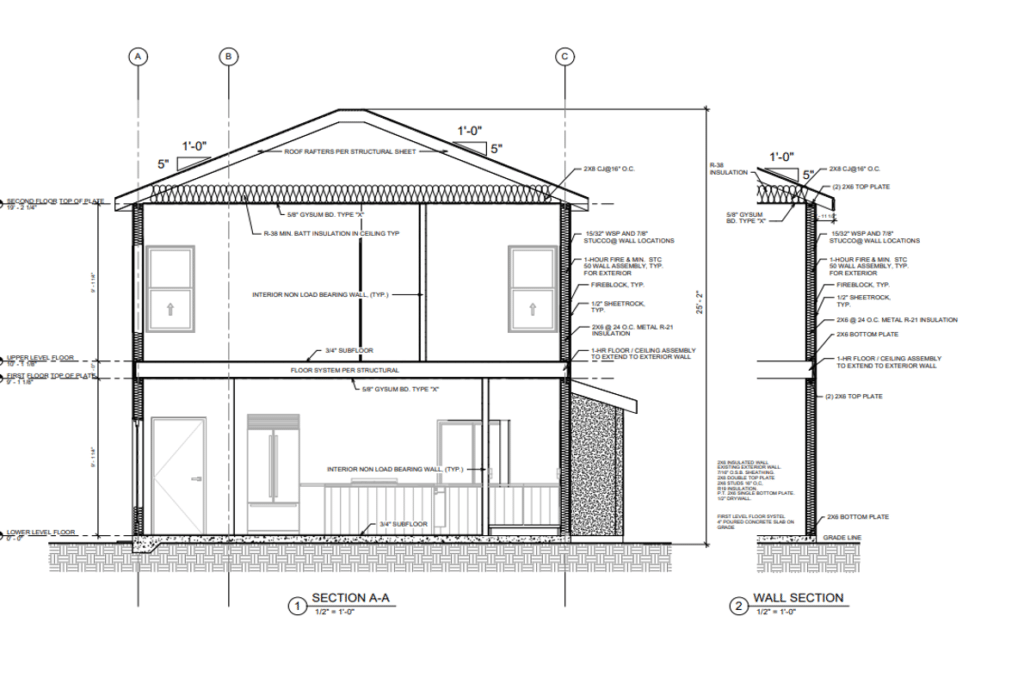

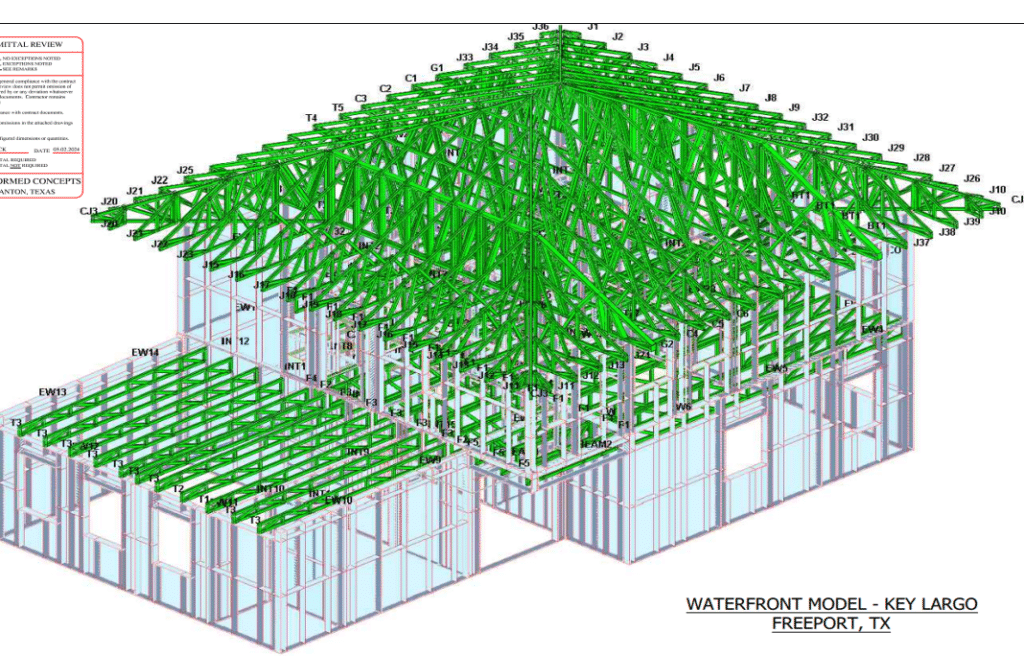

Framing Engineering Process

Timeline:

- The engineering for the framing will take approximately 4 to 6 weeks in most cases, it will depend on the project size . This process involves close collaboration between the architect or our engineer and the manufacturing team responsible for creating the building system. A CAD/DWG file will be required.

Joint Effort:

- The engineering and manufacturing teams will focus on various aspects of the building, including determining the spans and gauges of the cold-formed steel (CFS) sections, ranging from 16 to 20 gauge. The teams will utilize a combination of 5.5, 6-inch and 3.5 and3 5/8-inch studs, and depending on the size of the job and levels /storeys, they will be assessing the amount of red iron needed and identifying specific areas where it should be used.

Other Considerations:

- The teams will consider factors such as the foundation type and design, along with the anchors and fasteners for the building connections. We offer the capability to design and create the foundation and any type of foundation.

Building System Creation:

- Upon completion of the engineering, the CFS building system will be created for the building, ensuring a seamless construction experience. During fabrication, the manufacturing team will also utilize the MEP plans to pre-punch holes in the framing system studs for electrical and plumbing work. We can also add straps or extra studs where fixtures such as TVs, kitchen cupboards, or air conditioning units will be installed. Additionally, 2×4 or 2×6 wood blocking can be added on-site, as the CFS are C channels, facilitating easy wood blocking within the stud channels.

- The manufacturing for this structure will be completed at the closest fabrication facility and will take approximately 4 to 6 weeks at most.

- Post-Approval and Fabrication Process: 4 to 6 weeks

- Fabrication Commences: The fabrication of the frame begins as soon as the plans are approved, and grading and foundation construction are underway.

- Frame Delivery: The frame will arrive on-site, either in time for or before the foundation is ready, ensuring timely erection.

- Support and Assistance: We offer team support to assist with the erection process, especially for those new to working with Cold-Formed Steel (CFS).

- Ease of Construction: Our building system is designed for unskilled workers, providing comprehensive instructions and full support from our team to streamline the process.

Installation Support:

- Our installation support team will be on-site for up to 5 days to assist with the framing structure installation, answer any questions, and aid with the erection process.

Added Benefits

Strength and Durability

CFS steel studs are resistant to warping, shrinking, and splitting, ensuring the longevity of your structure.

Fire Resistance

Steel framing offers superior fire resistance, providing an added layer of safety.

Pest Resistant

Unlike wood, steel is impervious to termites and other pests.

Precision Engineering

Our CFS systems are manufactured to exact specifications, ensuring a perfect fit and faster construction times.

Cost-Effective

With reduced waste and quicker installation, CFS framing can lower overall construction costs.